General Maintenance

General maintenance serves two main purposes. First, it ensures the long-term durability of the musical instrument. Second, it guarantees proper operation and optimal tonal performance after the completion of all setup adjustments.

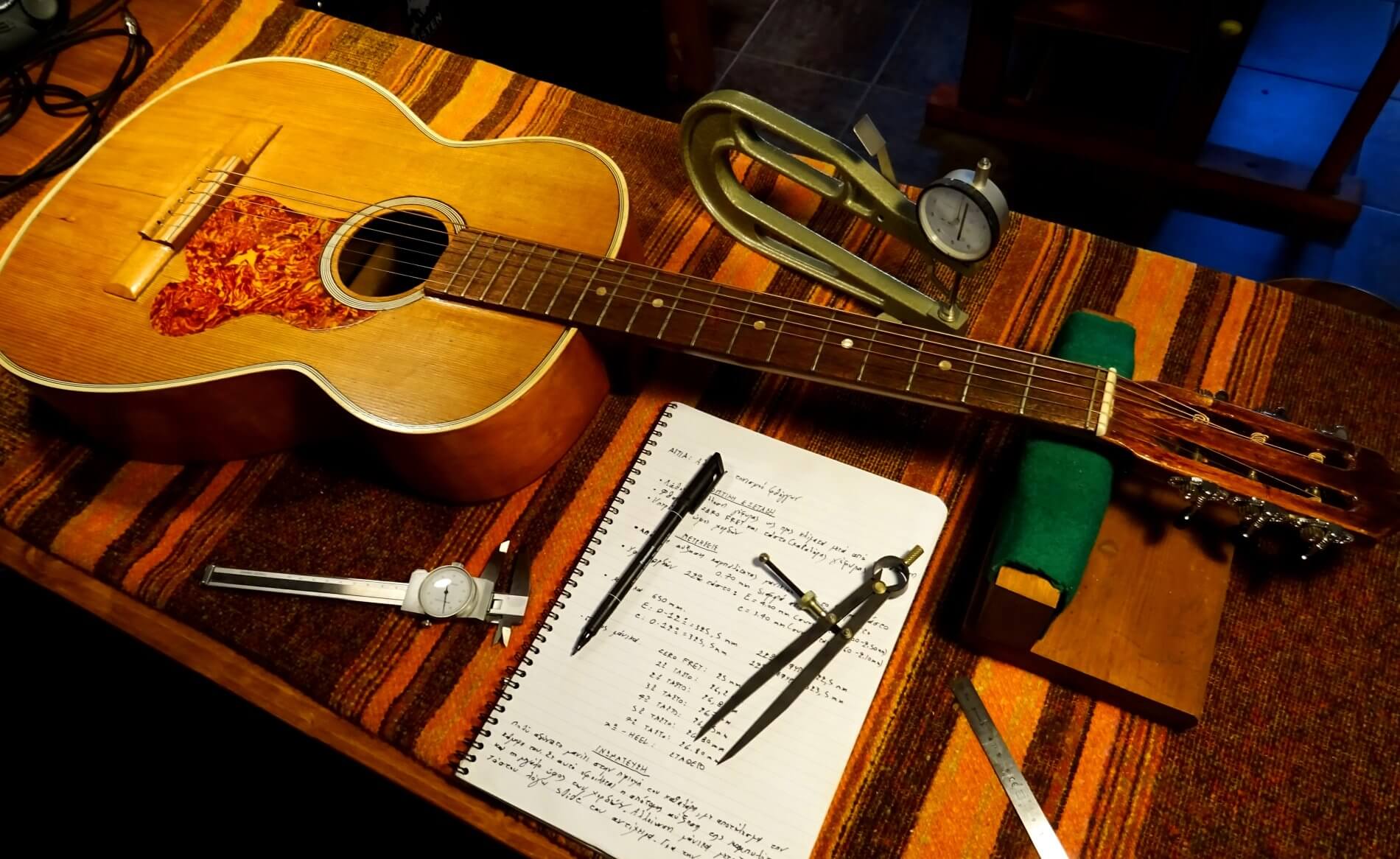

The first stage is a visual inspection, aimed at the initial detection of malfunctions and damage. All setup parameters present at the time of intake are recorded, along with the instrument’s particular characteristics and any modifications.

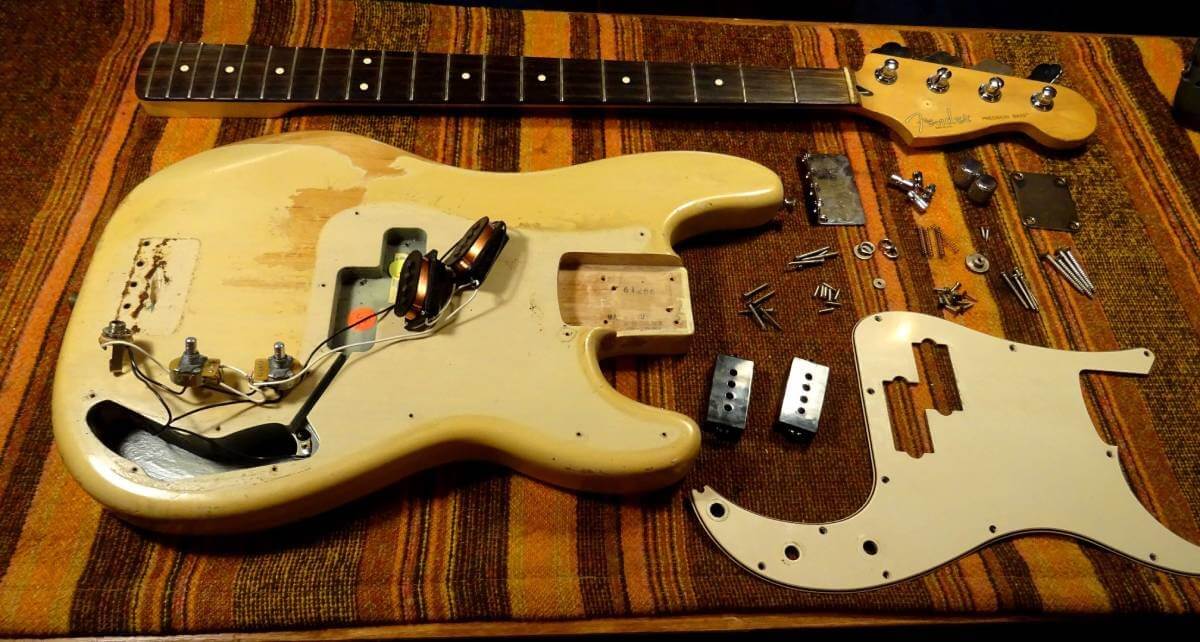

Next, the instrument is disassembled. All movable parts (hardware) are removed and thoroughly inspected. We examine the condition and functionality of all components, the body, and the neck. If the instrument is equipped with an electrical circuit, all electrical components and their wiring are checked. Through this process, even the most well-hidden faults and corrosions are identified.

The following stage is maintenance. Dirt and salt residues are removed from wooden and varnished surfaces, and metal surfaces are de-rusted. These contaminants and corrosions are usually caused by factors such as air oxidation, humidity, wear from friction caused by the performer during use, sweat, and skin oils. Depending on the nature of each surface, the appropriate tools and chemicals are selected to complete the process.

Afterwards, all vulnerable parts of the instrument are “shielded” to withstand the effects of the aforementioned factors, slowing down wear and corrosion. Bare wood is treated with oils or waxes to seal its pores and prevent deterioration of its molecular structure. Contact and friction points of moving parts are lubricated to ensure smooth operation, stable tuning, and the avoidance of unwanted noises.

For instruments with an electrical circuit, all conductive parts affected by oxidation and friction are cleaned. Potentiometers are opened to remove graphite residue from their tracks and are then lubricated. A similar procedure is followed for the instrument’s jacks.

Finally, the instrument is reassembled and fitted with strings. Basic functional adjustments are carried out before proceeding to high-precision operations for its final setup.